How Do You Make A Custom Sized Cardboard Box

Custom-sized cardboard boxes are essential for many businesses looking to package and ship their products safely and securely. Whether you are a small business owner or a large corporation, having the ability to create custom-sized boxes can streamline your packaging process and ensure that your products arrive at their destination in perfect condition. In this article, we will discuss how you can make a custom-sized cardboard box for your specific needs.

What is a Custom-Sized Cardboard Box?

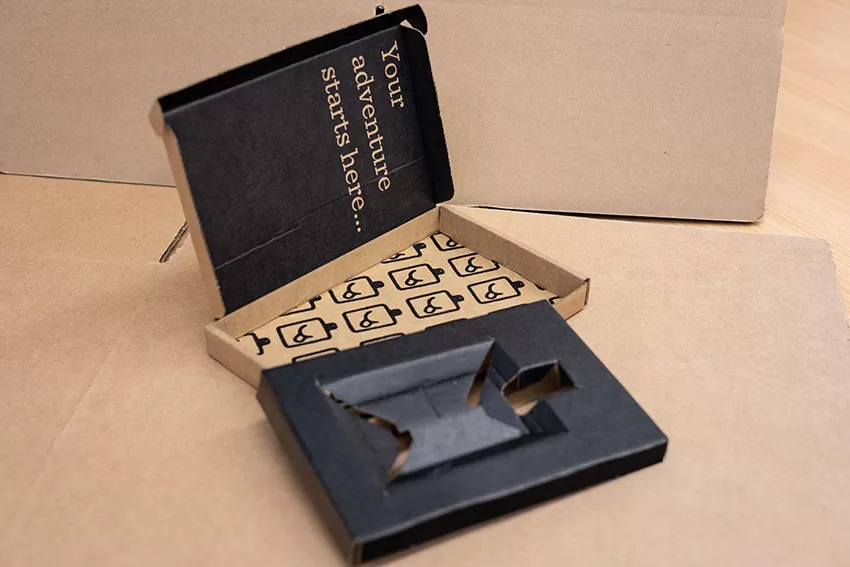

A custom-sized cardboard box is a packaging solution that is tailored to fit the dimensions of your product perfectly. By creating a box that is the exact size of your product, you eliminate the need for excessive packaging materials such as packing peanuts or bubble wrap, which can add to both the cost and environmental impact of your shipping process. Custom-sized boxes also help to prevent damage during shipping by securely holding your product in place and minimizing movement within the box.

How to Make a Custom-Sized Cardboard Box

Measure Your Product

The first step in creating a custom-sized cardboard box is to accurately measure your product. Take measurements of both the length, width, and height of your product, as well as any additional dimensions that may be relevant, such as the thickness of the product or any protruding features. Make sure to measure the product at its widest points to ensure that the box will fit snugly around it.

Choose the Right Type of Cardboard

Once you have your product dimensions, you will need to select the right type of cardboard for your custom-sized box. There are several options available, including single-wall, double-wall, and triple-wall cardboard, each offering different levels of protection and durability. Single-wall cardboard is suitable for lightweight items, while double-wall or triple-wall cardboard is better suited for heavier or fragile products.

Cut the Cardboard to Size

Using a sharp utility knife or box cutter, carefully cut the cardboard to the dimensions of your product. Make sure to use a straight edge or ruler to ensure clean, straight cuts. It is important to cut the cardboard slightly larger than your product dimensions to allow room for padding and protection inside the box.

Score and Fold the Cardboard

Next, you will need to score the cardboard along the fold lines using a scoring tool or the back of your utility knife. This will create creases in the cardboard that will make it easier to fold into shape. Carefully fold the cardboard along the scored lines to create the basic shape of your box.

Secure the Edges

To secure the edges of the box, you can use a strong adhesive such as packing tape or hot glue. Apply the adhesive along the edge of the cardboard and press firmly to ensure a strong bond. Make sure to reinforce the corners of the box with extra tape or glue to prevent them from separating during shipping.

Add Padding and Protection

Once the box is assembled, you can add padding and protection to ensure that your product is secure during shipping. This can include foam inserts, bubble wrap, packing peanuts, or paper filler. Make sure to fill any empty space inside the box to prevent your product from moving around during transit.

Seal the Box

Finally, seal the box securely using packing tape or adhesive. Make sure to reinforce the seams and edges of the box to prevent it from coming apart during shipping. You can also add additional labeling or branding to the box to customize it further for your business.

Benefits of Custom-Sized Cardboard Boxes

There are several benefits to using custom-sized cardboard boxes for your packaging needs, including:

Cost-Effective: Custom-sized boxes help to minimize the amount of packaging materials needed, reducing waste and saving money on shipping costs.

Eco-Friendly: By creating boxes that are tailored to the size of your product, you can reduce the environmental impact of your packaging process and promote sustainability.

Enhanced Protection: Custom-sized boxes provide a secure and snug fit for your product, reducing the risk of damage during shipping.

Professional Appearance: Custom-sized boxes can be customized with your branding or logo, creating a professional and cohesive look for your packaging.

Streamlined Packaging Process: Creating custom-sized boxes allows you to streamline your packaging process and improve efficiency in shipping and handling.

Conclusion

Making custom-sized cardboard boxes is a simple and cost-effective way to improve your packaging process and protect your products during shipping. By following these steps and considering the benefits of custom-sized boxes, you can create a secure and professional packaging solution for your business.